TOMBOW Pencil Co., Ltd. (Headquarters Kita-ku, Tokyo, President Akihiro Ogawa) announced the crack and break resistant MONO TOUGH eraser that is 8 times stronger than the standard Mono eraser and will go on sale from November 28 at stationery stores and mass retailers nationwide.

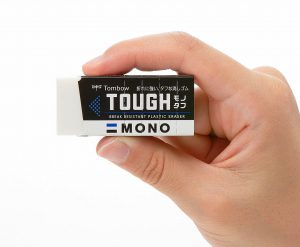

The MONO TOUGH is available in two sizes. The suggested retail price for the large size (23 x 11 x 55 mm) is 100 yen (110 yen including tax) and for the small size (17 x 11 x 43 mm) 60 yen (66 yen including tax). (See photo)The price is the same as the standard “MONO PE”. Annual sales plan for this product is 2.3 million pcs total for both sizes, 180 million yen (at retail prices).

This product addresses the most common claim from students that erasers often crack and break.Eraser corners often crack during use and the sleeve (paper case) cuts into the eraser material causing cracks which lead to breaks. A unique eraser compound and manufacturing process increases flexibility as well as hardness to eliminate these problems.A balance was achieved between eraser performance and creation of eraser dust.

At the same time an original design diagonal cut paper sleeve that prevents cracks and damage was adopted so the overall design prevents damage related to strong erasing pressure.

This eraser has the strength to withstand unexpected erasing pressure during intense study and academic achievement tests.

Even though the eraser material was hardened, erasing performance is excellent.

The material is the same plastic as used for our standard “MONO PE”, but the strength is about 8 times more. “Bend strength test” *1 The highest strength of all our erasers.

Even with the hardened plastic the erasure rate (*2) is 95% vs. our standard MONO PE products 97%. Balanced strength and erasing performance.

From a technical perspective special additives were added to the plastic compound and a unique processing method was devised to ensure strong physical properties and dramatically improve strength.

* 1 “Bend strength test”: Our original test method. Measures strength when applying reciprocating (back and forth) pressure to the eraser.

* 2 Erasing rate: A written line on paper is erased under controlled conditions, the line density is measured, and the remainder is calculated as a percentage.

Newly adopted “diagonal cut sleeve” to reduce eraser stress

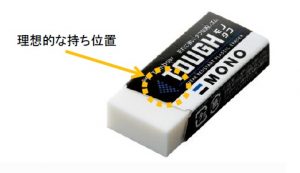

In order to prevent the sleeve from cutting into the eraser which causes the eraser to tear and break, a unique “diagonal cut sleeve” (patent pending) was devised. (See photo)

The causes of cutting and tearing are as follows: (1)The eraser bends due to erasing pressure and the paper sleeve cuts into the plastic material causing cracks. (2)The back and forth (reciprocating) pressure on the eraser deepens these cracks, and (3) further back and forth pressure causes a break.

In response to this phenomenon rather than concentrating the force in one place, the “diagonal cut sleeve” design distributes pressure on the plastic dispersing the force to reduce the risk of cracking.

Other features

■ Diagonally perforated paper sleeve allows adjustment of sleeve length as the eraser wears.

■ Ideal grip position indicator on the sleeve to further lessen the chances of breaking.

■ Green Purchasing Law Compliant Product